Aaron resides in the City of London with his mother Ava and Father Dylan. He is a student at the City of London School, which is on the banks of the river Thames in the City of London, next to the Millennium Bridge, opposite Tatemodern. His schools have been closed due to the corona virus. There is a lockdown across the UK.

His studies were suffering a lot. But soon the school administration announced that from now on the classes of the children would be online. Aaron did not have a laptop. So he requested his father to bring him a laptop. When his father went to the market to get a laptop for him, he found that there was a shortage in the market of the laptop.

When his father Dylan tried to find out the reason for the short supply of laptops in the market, he came to know that the lack of supply of laptops is due to a chip of only five to 10 nanometers. Also called semiconductor chip.

This is not only the story of Aaron, not knowing how many such stories are there. There has been a problem in the supply chain of all things, whether it is laptop freeze, car mobile, due to the shortfall of the semiconductor chip.

In December of 2019, the corona virus that originated from Wuhan city of China changed the economy of the world. It has affected the economy as well as the common life of the people. Let us now know in detail about the semiconductor chip –

- Semiconductor chips are also known as microchips. It is made of Silicon, Germanium and Gallium Arsenide.

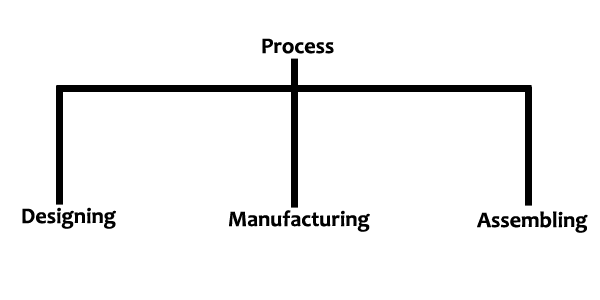

- The companies that design the chip are known as Fabless firms. Where their designs are manufactured, they are known as fab industrial units. The third stage where this assembly, testing and packaging takes place is known as OSAT unit. Intel, Texas Instruments, Samsung, Nvidia and Foxconn are the major chip making companies.

- The first stage of chip making is research and development. It requires a lot of research. Along with this, the designing of the chip also happens in this phase. Most companies invest 20% of their revenue on R&D. A critical and high-skilled work force is required to make the chip.

- Along with this, 20 million liters of ultra pure water is required per day to make the chip. Pollution free environment is very important inside the factory. So that no particle can touch the chip. Along with this, stable power supply is also required.

- Semi conductor is the property between conductor and insulator. If we talk about its use, then it is used in cars, laptops, smartphones, home appliances and games. The demand for electric electronic devices has increased during the Covid-19. As online education requires laptop or mobile for online education, then the demand for laptop and mobile has increased. The demand for medical devices has also increased in covid. Such as heart beat pulse measuring machine, thermometer etc.

- Microchip i.e. semiconductor chip is made up of simple raw materials sand. That sand is made of silicon dioxide and silica. Complex chemical and physical processes demand that it be ensured that silicon crystals meet the high production standards that are applied to the chip.

- To convert silica sand to silicon, sand is combined with carbon and heated to a high temperature to remove oxygen. Silicon is a semiconductor. Which can also conduct electricity.

Every transistor on a chip contains-

P- conductive

N- conductive

The layer of semiconductor chip is made of silicon crystals. Whereas the additional layer is made of silicon oxide which acts as an insulator. Polysilicon is applied on top of it. A clean room is required to make the chip. Where there are no particles of dust. It takes 26 weeks to make.

To make semiconductors, a raw material called silicon is required, which is available in abundance. The Fourth Industrial Revolution was impossible without semiconductors. China remains the world leader in semiconductors. While Taiwan is also a big name in this. Semiconductor chip designing, manufacturing and packaging is done in the United States, China, Taiwan, South Korea and Japan.

Taiwan’s TSMC company is a big name in this. Taiwan is the largest chip manufacturing country. It has a 63% share in the global supply chain. There are chip making companies like Samsung, Nvidia, TSMC, Foxconn, Qualcomm etc. Workers are taken from Vietnam, Malaysia, Philippines and China to make the chip.

The US accounts for 50% of the chip production market. In this, Intel, Nvidia, Texas Instruments, Broadcom, MD and Global Foundries are the major companies of America. It has major chip making companies like Samsung of South Korea, TSMC & UMC of Taiwan and SMIC of China.